Products

INCHR is a pioneer in the professional manufacture of permanent antistatic agents and masterbatches. In terms of performance, the products have long-lasting and stable antistatic properties. The selection of raw materials is demanding, and we only cooperate with the world’s top suppliers, relying on advanced automation technology to ensure the consistency and accuracy of the products. Our efficient production and optimized integrated supply chain ensure high quality while creating a highly competitive price advantage, making it an ideal choice for your antistatic needs.

About Us

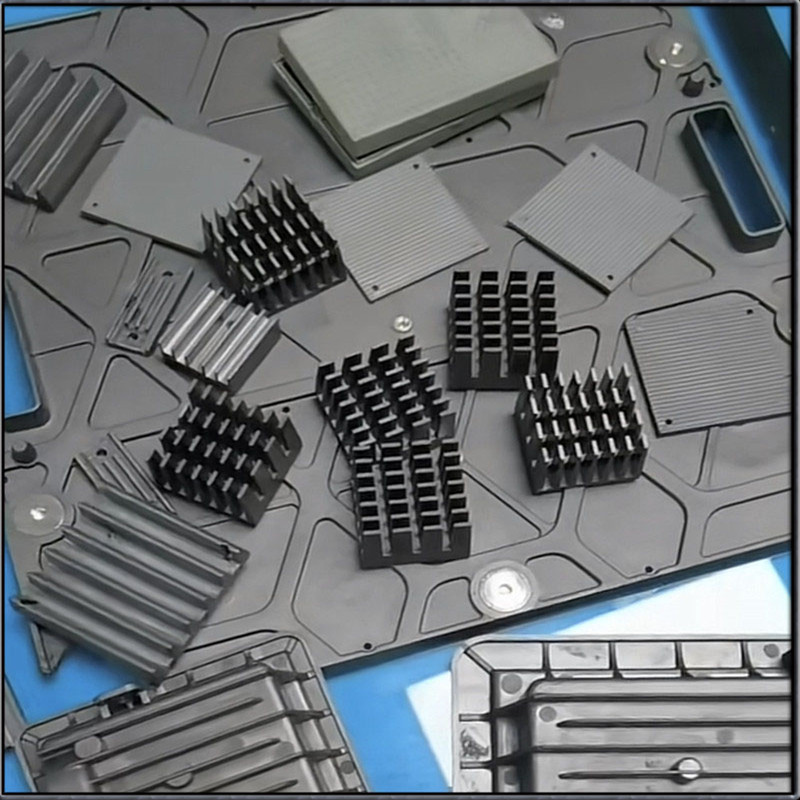

ESD plastic is an excellent protection solution, which not only suppresses the generation of static electricity, but also prevents its accumulation, effectively protecting sensitive equipment such as electronic components, and eliminating the potential safety hazards caused by it. In the manufacturing industry in China (mainland), INCHR stands out.

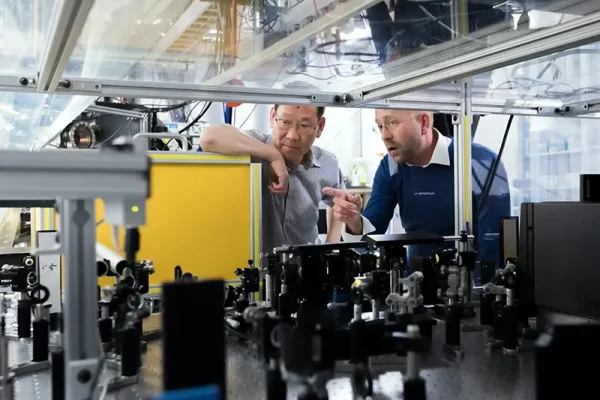

INCHR is a professional ESD plastic manufacturer that relies on strong R&D capabilities, a professional and efficient scientific research team, and complete and advanced R&D facilities. When faced with various static electricity problems, INCHR can respond quickly, and with its profound technical accumulation and rich practical experience, it can quickly and accurately tailor a complete set of static electricity problem solutions for customers.

Our Advantages

- Professional team: We have an experienced and diverse professional team which have been working in ESD plastic research and development, formula design, market application, and other fields for many years and has accumulated deep industry knowledge.

- Customized development: Experts respond quickly to customers’ special application needs, jointly develop exclusive formulas, and create special products that fit the market and satisfy customers.

Our Obligation

- Quality assurance: Adhere to high-quality product output, strictly control quality from raw material procurement to the production process, and provide professional and considerate services to create a good reputation.

- After-sales service: Set up 24/7 service technical support to solve technical problems in the process of customers using products at any time to ensure continuous operation of the business.

Our Vision

- Innovative achievements: Continue to focus on the research and development of new ESD plastics, and have successfully launched graphene-enhanced composite materials, rewriting the industry application pattern.

- Future goals: Face challenges, deepen the field of innovative plastic raw materials, and aspire to become a world-class technical expert and lead the industry’s technological upgrades.

Our Service

Quick response and service in 24 hours.

INCHR not only supplies ESD plastics but also provides solutions for static dissipation.

We offer customization according to the customer’s requirements, including the whole service from color design, and product development to molding condition.

R&D And Innovation

- R&D team focuses on the research and innovation of formulation and application. Our lab is equipped with a full range of advanced testing devices in ASTM/ISO that ensure consistency and repeatability

- Professional and experienced R&D personnel are the core of our R&D team. We all have PhDs in polymers and have been maintaining industry technology exchanges and cooperation with universities in related industries.

- Our laboratory features a data management system to record and store customers’ proofing and experimental data in a timely and accurate manner.

You should know about ESD plastics

- Antistatic plastics: Adding antistatic agents or conductive masterbatch to resins to give them certain antistatic properties and be able to release static electricity promptly. The surface resistivity is usually 10^6~10^12 Ohms/sq.

- Conductive plastics: Conductive fillers such as carbon fiber, CNT, graphene, or special conductive masterbatch are added to matrixes to give them certain conductive electrical properties, so we can quickly discharge static electricity. The surface resistivity is usually 10^2~10^6 Ohms/sq.

- ESD rubber: The plastic material has good electrical and chemical properties and is often used in seals and interfaces of electronic equipment. Common rubbers include EPDM, NBR, SBR, etc., which are suitable for open mixing, internal mixing, and other processes.

ESD plastics are widely used in industries that are sensitive to static electricity, such as electronic component manufacturing, semiconductor production and transportation, medical equipment, and automotive processes, to ensure product quality and reliability and reduce failures and damage caused by electrostatic discharge.

What factors should be considered when selecting ESD plastics

Electrostatic performance options

Determine the key indicators such as the electrostatic dissipation rate, and surface or volume resistance. The lower the resistance value, the better the conductivity and the stronger the electrostatic dissipation ability. However, the appropriate resistance range should be determined based on the electrostatic sensitivity of the specific application.

Substrate and mechanical properties options

According to the electrostatic protection requirements and the use environment of the product, select the appropriate matric resin, such as general plastic or engineering plastic. Different processing technologies can choose the right ESD plastics, such as the strength, flexibility, and wear resistance.

Working environment

Consider the temperature and humidity conditions of the application scenario. The performance of some ESD plastics may change under different temperatures and humidity. For example, the working temperature of ESD PC compound is higher than that of ESD ABS compound.

Price and overall cost

The prices of different ESD plastics vary greatly. Cost factors should be considered on the premise of meeting performance requirements.

Cleanliness requirements

For some applications with high cleanliness requirements. For example, in semiconductor manufacturing, the selected materials should be easy to clean and will not cause pollution, and even the transparency of ESD plastics is required to be high.

Durability

Evaluate the service life and reusability of the material. For example, ESD POM is a wear-resistant material.

Chemical compatibility

If the ESD plastic is exposed to specific chemicals, it is necessary to ensure good chemical stability and compatibility.

Regulations and standards

Some industries have specific ESD protection regulations and standards, and the selected materials should meet the relevant requirements.